How Many Wires Can You Fit in a Junction Box?

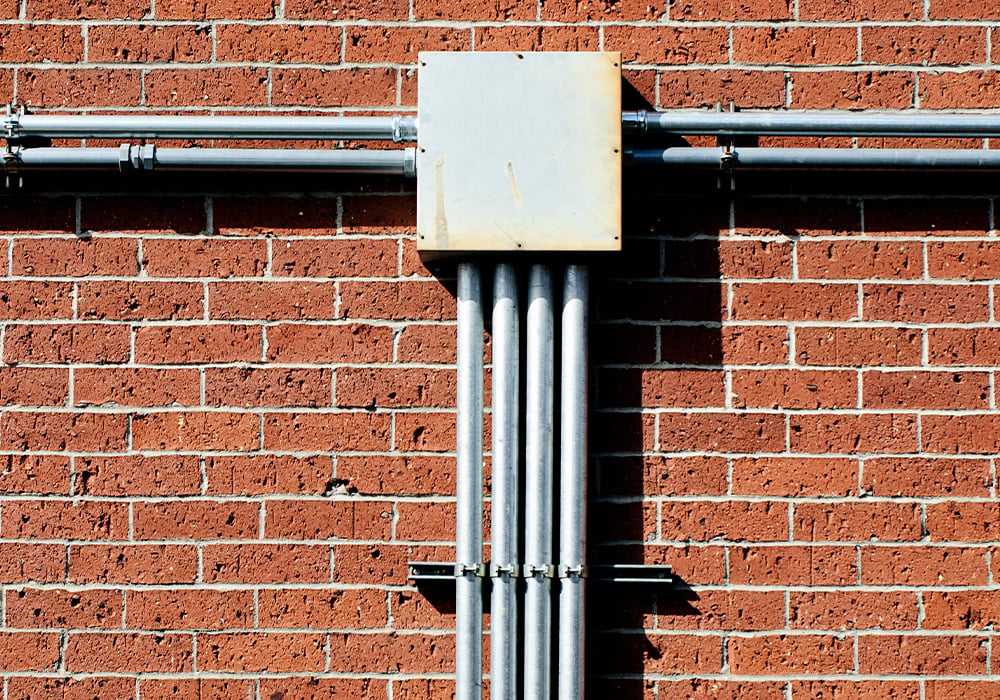

Junction boxes, or electrical boxes, are essential components in any electrical system. These enclosed spaces secure and protect electrical connections, ensuring a safe and efficient flow of electricity. One vital aspect of junction box installations is understanding the capacity and limitations associated with the number of wires contained within the box.

The capacity of a junction box depends on two primary factors: the size of the box itself and the size of the wires being used. Different wire gauges, or thicknesses, affect the number of wires that can fit inside a junction box, and understanding these variations is crucial for ensuring an efficient and safe electrical setup. Additionally, it is essential to be aware of the importance of avoiding overfilling, proper wire bending, and compatibility between wire sizes and the box sizes to maintain optimal system performance and adhere to safety guidelines.

Key Takeaways

- Understanding the junction box capacity involves considering the box size and wire gauge

- Different wire gauges have different limitations, which affect the number of wires that can safely fit inside a junction box

- Proper wire bending, compatibility between wire and box sizes, and avoiding overfilling are crucial for maintaining safety and efficiency in an electrical system

Essentials of a Junction Box

A junction box serves as an essential element in electrical installations, providing a safe and secure space for connecting wires. To determine how many wires you can fit in a junction box, there are two key factors to consider: the size of the box itself and the size of the cables or conductors.

The capacity of a junction box depends on its size. For example, a 4-inch square box that is 1 ¼-inch deep can accommodate up to eight #12 wires, nine #14 wires, or ten #16 wires. In contrast, a 4-inch square box that is 2⅛-inch deep can hold more wires.

Junction boxes come with varying numbers of terminals, ranging from 3 to 6. The terminals are where you will make wire connections by inserting the wire core from either side of the wiring run and then screwing the terminal close, creating a safe electrical junction and connection.

When wiring a junction box, it is important to adhere to the National Electrical Code (NEC) rules for ensuring safety. These rules outline the maximum number of wires and splices allowed in outlet, pull, and junction boxes.

In conclusion, determining the number of wires that can fit in a junction box depends on the box’s size and the size of the conductors used. Always follow NEC guidelines to ensure safety and adhere to relevant local regulations.

Understanding Wire Gauges

When determining how many wires can fit in a junction box, it is important to understand wire gauges. The wire gauge refers to the diameter of the wire, and it is crucial in calculating the maximum number of wires that can fit into a specific junction box. The bigger the gauge, the smaller the wire.

The American Wire Gauge (AWG) system is commonly used to denote wire sizes, with smaller numbers indicating larger diameters. For instance, a 14 AWG wire will be thicker than a 16 AWG wire. It is essential to know the size of your wire to adhere to safety standards when installing electrical connections.

Different wire gauges cater to various applications based upon the amount of current they can safely carry. For instance, a 14 AWG wire can carry 15 amps, while a 12 AWG wire can handle up to 20 amps, and a 10 AWG can carry 30 amps. Understanding the specific requirements for your project ensures the safe and efficient function of electrical connections within a junction box.

Moreover, the capacity of a junction box depends on the volume of the box itself. You can find this information in cubic inches on the packaging or manufacturer’s documentation. By determining the cable size and taking into account the required cable fill, you can ensure that the electrical connections are neatly housed in the junction box without overcrowding or violating any safety guidelines.

In summary, when fitting wires into a junction box, consider both the wire gauge and junction box size to make safe and efficient electrical connections.

Junction Box Capacity

When determining the capacity of a junction box, it is important to consider two key factors: the size of the box itself and the size of the cables or conductors. The National Electrical Code (NEC) has specific guidelines on how many wires can be safely placed within a junction box.

Firstly, you must measure the internal dimensions of your junction box to determine its cubic inch capacity. To calculate this, simply multiply the length, width, and depth of the box. For instance, if your box measures 4 inches by 4 inches by 2 inches, the cubic inch capacity would be 32 cubic inches.

Next, take into account the size of the wires that will be housed within the junction box. The NEC provides specific guidelines for the maximum number of conductors allowed in a given box size, taking into account the wires’ gauge, or cross-sectional area. For example:

- For 14 AWG wires, each wire requires 2 cubic inches of space.

- For 12 AWG wires, each wire requires 2.25 cubic inches of space.

Considering these wire gauge requirements, you can determine the number of wires that can fit in your junction box by dividing the box’s cubic inch capacity by the cubic inch space required for each wire.

Remember, these calculations are only for the conductors, and you must also factor in any devices (such as switches or receptacles) that will be installed in the box. Typically, each device requires double the space of its largest connected conductor.

By considering these factors and adhering to the NEC guidelines, you can ensure that your junction box is safely and appropriately filled. Remember, overloading a junction box can lead to overheating, which poses a risk of electrical fires. It is always better to err on the side of caution and adhere to the established guidelines when working with electrical systems.

Determining Numbers of Wires

The number of wires that can fit in a junction box depends on two key factors: the size of the box and the size of the cables or conductors. To determine the number of wires that can safely fit in a junction box, you’ll need to follow these steps:

- Identify the box size: First, measure the length, width, and depth of the junction box in inches. Multiply these measurements together to determine the total box volume in cubic inches. For example, if you have a junction box that measures 4 inches in length, 4 inches in width, and 2 inches in depth, the total box volume is 32 cubic inches.

- Determine the cable fill capacity: Consult the National Electrical Code (NEC) installation guidelines. The NEC provides a table with the required box fill capacity for each wire size. Find the wire size you’re using and note the required cubic inches per conductor.

- Count the number of conductors: Count each wire entering the junction box. Additionally, count fittings, clamps, and devices, such as switches and receptacles, by assigning an equivalent conductor value to each based on the NEC guidelines.

- Calculate the total fill capacity: Multiply the number of conductors by the required cubic inches per conductor. Add these values together to get the total fill capacity required for the junction box.

For example, if you have the following wires and devices in a junction box:

- 4 conductors of size #14

- 1 conductor of size #8

- 2 cable clamps

Using the NEC table, you find that #14 wires require 2.00 cubic inches per conductor, and #8 wires require 3.00 cubic inches per conductor. Cable clamps require 0.50 cubic inches each. So, the total fill capacity needed for this junction box is:

(4 x 2.00) + (1 x 3.00) + (2 x 0.50) = 11 cubic inches

- Check if the junction box is suitable: Compare the total fill capacity with the box volume. If the total fill capacity is less than or equal to the box volume, the junction box is suitable for the number of wires and devices. In our example, 11 cubic inches is less than the box volume of 32 cubic inches, so the junction box is suitable.

By following these steps, you can determine the appropriate number of wires for a junction box and ensure a safe installation that meets the NEC standards.

Types of Wires and Their Effect

When planning your wiring project, it’s essential to consider the types of wires you’ll be using. This is because different wire types can affect how many wires you can safely fit in a junction box.

Firstly, consider wire size. Wires are generally measured in American Wire Gauge (AWG), which refers to the diameter of the wire. For instance, 14 AWG is a common size for residential wiring, while 12 AWG is often used for larger electrical loads. The bigger the AWG number, the smaller the wire diameter, and consequently, you can fit more wires of a smaller AWG size in a junction box compared to a larger one.

Additionally, the insulation material covering the wire can also play a role in how many wires you can accommodate in a junction box. Insulation materials, such as thermoplastic or thermosetting, can vary in thickness and heat resistance. If your wires have thicker insulation, you may need a larger junction box to fit the allowable number of wires safely.

Lastly, the type of electrical circuit you’re working on may impact the number of wires in the junction box. For example, a lighting circuit typically requires a 20 amp junction box, while a ring main or radial circuit needs a 30 amp junction box. Be sure to select the appropriate junction box for your specific project to ensure safety and compliance with electrical codes.

When calculating the appropriate wire capacity for a junction box, abide by the guidelines laid out by the National Electrical Code (NEC), which dictates rules for electrical installations. Doing so will help ensure that your project is both safe and efficient, allowing for successful installation and performance.

Importance of Avoiding Overfilling

It’s crucial for you to avoid overfilling a junction box when installing electrical wiring in your home. Overfilling a junction box can cause a range of problems, including overheating, short circuits, and even electrical fires. Besides causing potential hazards, overfilling might also lead to violations of building codes and regulations.

To ensure the safety of your home and comply with the law, you need to consider a few factors while wiring a junction box. First, the number of wires that can fit in a junction box depends on its volume. Smaller boxes can accommodate fewer wires than larger ones. It’s important to select a junction box with the appropriate volume for the number of wires you plan to install.

Another factor to take into account is the gauge of the wires used in the junction box. The wire gauge determines the thickness and current-carrying capacity of the wire. Thicker wires occupy more space, thereby limiting the number of wires that can fit in the junction box.

In addition to the gauge and volume, you should consider the presence of other components inside the junction box, such as cable clamps, outlets, switches, and other objects. These components take up space in the junction box, leaving less room for wires.

In summary, it’s essential to avoid overfilling a junction box to ensure the safety and compliance of your electrical system. Take the time to calculate the volume, wire gauge, and presence of additional components in the junction box to avoid overcrowding and prevent potential hazards.

Wire Bending Space

When you’re determining how many wires you can fit in a junction box, one essential factor to consider is wire bending space. The space within the box must be large enough to accommodate the electrical connections while allowing for proper wire bending without causing any strain or damage.

The size of the junction box itself plays a critical role in determining the number of wires it can safely accommodate. Typically, larger boxes can house more conductors, but it’s essential to adhere to the guidelines set forth by the NEC or any relevant local electrical codes.

To calculate the allowed wire bending space in a junction box, consider the size and type of cables you’re using. For instance, different AWG sizes will require varying amounts of space. It’s crucial to ensure that the box has enough room for all the conductors you plan to use, as well as any additional elements such as connectors, clamps, or switches.

When arranging wires within the junction box, be sure to:

- Keep similar conductor types together (e.g., live to live, neutral to neutral, and earth to earth)

- Securely fasten each connection with terminal screws, ensuring they are tightened appropriately

- Avoid overcrowding the box, which could lead to overheating or connection issues

Additionally, utilising the proper wire connectors is vital for ensuring the box’s safety and functionality. Choosing connectors based on the wire’s size and insulation type helps maintain secure connections while preserving the integrity of the insulated material.

In summary, calculating the wire bending space in a junction box involves considering the box’s size, the cable types, and the number of conductors required for your electrical project. By ensuring that your junction box has enough space and is organised correctly, you can create safe and efficient electrical connections.

Wire Size and Box Size Compatibility

Selecting the right size junction box for your project is essential for maintaining safety and ensuring proper function. To determine the appropriate junction box size, you need to consider two main factors: the size of the wires and the total number of wires.

When selecting a junction box, it is essential to consider the wire gauge (also known as the wire size). The wire gauge refers to the diameter of the wire, which directly impacts the current-carrying capacity and electrical resistance. Common wire gauges include 14 AWG, 12 AWG, and 10 AWG, with smaller numbers representing thicker wires.

The electrical code provides guidelines for the maximum number of wires permitted in a junction box based on the size of the box and the gauge of the wires involved. To calculate the box fill capacity, every wire, device (such as switches or receptacles), and clamp contributes to the overall number of conductors.

Ensure your junction box is compatible with the wire size and total conductors for safety and adherence to regulations. These requirements often vary depending on:

- Cable size: The size or gauge of the wires you’re using will affect the box fill capacity. Thicker wires require more space, so when using larger gauge wires, make sure the junction box is large enough to accommodate them.

- Total conductor count: Each wire, clamp, and device contributes to the total conductor count, impacting the required box size. It is essential to consider all components of the electrical installation when choosing the most suitable junction box size.

By understanding the wire size and box size compatibility, you can ensure a safe, efficient, and code-compliant electrical installation. Proper selection of junction box size will allow for an organized, secure, and easily accessible connection point for all necessary wiring.

Safety Precautions for Filling a Junction Box

When dealing with electrical connections, always take safety precautions to ensure your well-being and the proper functioning of the installation. In a junction box, the number of wires that can safely fit depends on the size of the box and the size of the cables or conductors. Here are some safety measures to follow:

1. Choose the correct junction box size: Junction box sizes vary, and choosing the right one is essential for accommodating the maximum number of wires that you need to connect. Keep in mind that overfilling a junction box can lead to overheating and potentially hazardous situations.

2. Check the maximum number of conductors: Each junction box has a maximum number of wires allowed, usually indicated on the box itself or in the product datasheet. Adhere to this maximum limit to avoid any risks.

3. Follow the Wiring Regulations: Make sure to comply with the Wiring Regulations BS 7671, which ensures that electrical installations are designed, constructed, installed, and tested safely and efficiently.

4. Maintain proper connections: When connecting wires inside the junction box, use the appropriate connectors (for hot, neutral, and ground) and tighten the terminals to establish a secure electrical junction. Loose connections may cause heating or arcing, leading to potential hazards.

5. Organise the setup: Properly arrange the wires inside the junction box, ensuring that they do not overlap or tangle. Keeping the wires organised will make it easier for future maintenance, troubleshooting or modifications, and help prevent any hazardous situations.

6. Wear protective gear: Last but not least, always put on appropriate personal protective equipment when working with electrical installations. This includes gloves, safety goggles, and occasionally, insulated tools.

By following these safety precautions, you can limit the risks associated with filling and working with junction boxes, while maintaining both your safety and the integrity of your electrical system.